Positive Pressure Grease System

The Absolute Control PPGS allows your personnel to maintain grease pressure in the valve cavity at a safe distance from the red zone. Reducing equipment damage by maintaining grease pressure within the cavity. These units have the ability to monitor multiple hydraulic lines and either pump on demand, maintain a set pressure or maintain an offset pressure that tracks with the pump pressure. Our systems are designed to operate on any grease pump and record data throughout the job. The units also monitor grease volumes via stroke counter.

Download Brochure Here

Bringing portable efficient and accurate maintenance technology to the field.

-

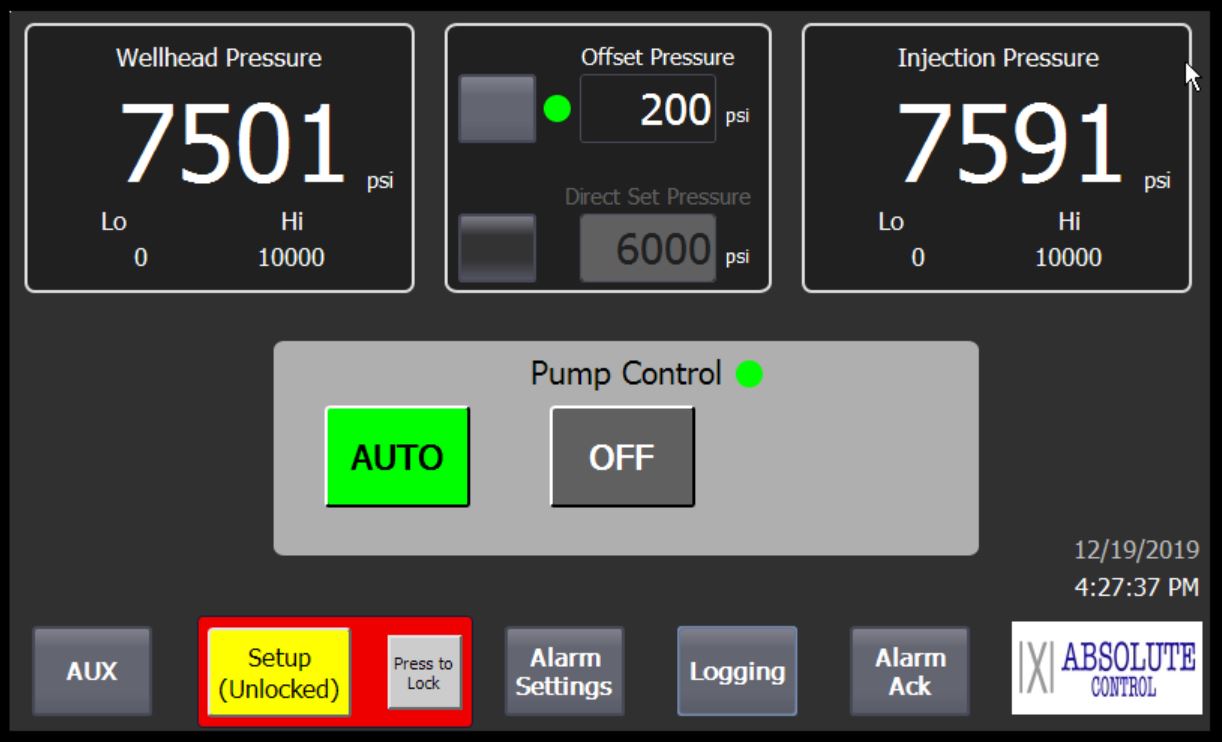

- The easy read display puts all the essential data in one location allowing for on-the-spot adjustments

- Automatic or manual pump modes

- The reliability of the digital pressure sensors reduces the risk of over greasing

- Allows for constant well head pressure monitoring

- Designed to monitor multiple grease lines

- The system stores entire job profile to local USB drive in easy to read excel format

- System operates pneumatic supply valve for grease based on preset user input

- Reduces red zone exposure and the dangers of working near pressurized equipment

- System records data in case of an over-pressure event

- Comment logging field available when recording

- Auto pumping based on set pressure or offset pressure

- User friendly setup for sensors and field calibration

- Stroke counter displays grease volume for both job and well totals

Additional information

| Description | PPGS |

|---|---|

| Operating Source | 120 Volt Single Phase |

| Grease lines to monitor | 6 lines |

| Grease pump control | Electric pneumatic solenoid |

| Pump pressure sensors | 2” 1502 Digital |

| Screen | 7” touch |

| Stroke Counter | Magnetic |

| Recording format | Excel |

| Recording device | USB |

| Weight | 24 lbs. |

| Dimensions (LxWxH) | 12” x 8” x 18” |